urban-gro, Inc’s team of expert engineers and designers have developed an innovative process for cultivation space design.

In this article, urban-gro, Inc explains more about its high performance cannabis facilities.

As expert engineers and designers of high performance cannabis cultivation facilities, it is our job to create cultivation facilities that exceed our customers’ goals for efficient interaction between the people, plants, environment and processes critical to the economic success of the facility.

Cultivation space programming for living buildings

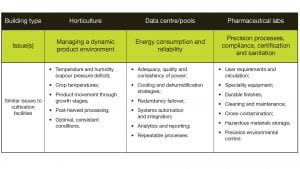

Today’s modern cultivation facility is a blend of multiple building types: the dynamism of living plants found in a horticulture facility, the precision process cooling systems found in a data centre, the intense humidity loads found in indoor swimming pools; and the precision operations and sanitation requirements of pharmaceutical-grade laboratories. The attributes of each building type combine to contribute to the economic success of a high performance cultivation facility. Fig. 1 outlines several key considerations of each building type.

urban-gro’s cultivation space programming, along with our mechanical, electrical and plumbing (MEP) engineering team and in conjunction with architectural and general construction partners, has integrated the best practices of horticulture, data centres and pools, and pharmaceutical-grade labs. This integrated turnkey approach provides customers with high performance cultivation facilities which are sustainable, efficient and cost effective; maximising yields, plant health and profitability.

When should you engage with cultivation space planning?

It is generally assumed that a cultivation facility is designed via collaboration between architects, engineers, and speciality consultants. In the early days of commercial cultivation facility design, there was little consideration given to the interaction between plants, people and processes. As the cannabis industry has matured, we now recognise that high performance spaces need to be deliberately mapped out using cultivation space planning.

Cultivation space planning begins prior to the start of the design process. It is the foundation of an organised, informed approach which enables the business and cultivation functions to work together to efficiently produce economically competitive cannabis. This approach also ensures due consideration is paid to the facility layout, ensuring compliance in a highly regulated market.

Cultivation space programming drives your business goals

The goals of your business are the driving factors behind cultivation space programming. You can determine how your space will be utilised in order to reach your intended production and quality goals.

Proper planning of the entire cultivation facility leads to higher levels of productivity and performance. With an organised facility, it is easier to complete critical tasks that support product quality and compliance. With an efficient layout, employees are better equipped to work together and develop solutions before issues become problems.

In a cultivation facility, every square foot is valuable. Every mistake made at the design stage means that operational efficiency is sacrificed, yields are decreased and crop quality is reduced.

Cultivation space programming engagement and process

Conducting space programming benefits the entire cultivation team. By asking the appropriate questions, the right amount and type of space, equipment and furniture needed can be purposefully assigned and understood.

The following are key elements of cultivation

Space programming:

- Identify and engage project stakeholders: the successful design and operation of a cultivation facility requires the input of owners, occupants and subject matter experts who help to inform the design and construction teams about unique aspects of the facility;

- Build consensus around market strategy: business goals are expressed in the design and use of each space in support of the cultivation operational practices;

- Facility evaluation: a comprehensive evaluation of the facility, including cultivation requirements and business objectives (and identifying possible limitations) to ensure the site can achieve stakeholder goals;

- Benchmark plant density and production goals: utilising throughput calculations based upon commercial horticulture production to ensure streamlined and efficient movement of plants throughout the facility; and

- Establish workflow and circulation: document a clear understanding of how employees will move through the spaces while doing their jobs.

Cultivation space programming: three case studies

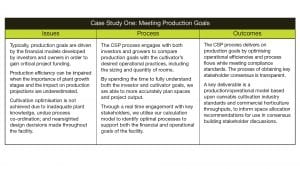

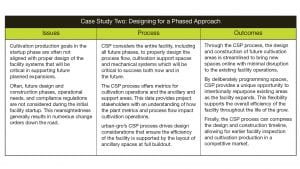

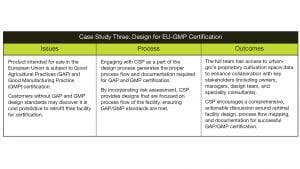

These case studies examine the process and outcomes of urban-gro’s cultivation space programming in three unique cultivation facilities. Having designed and commissioned more than 300 facilities and cultivation systems, these case studies collectively represent the most prevalent issues across regulatory and geographically diverse markets:

- Meeting production goals;

- Designing for a phased approach; and

- CSP supports GAP and GMP certification.

Data drives cultivation space planning

Having designed and commissioned more than 300 facilities and cultivation systems, we have developed a proprietary dataset of aggregated, anonymised cultivation facility metrics.

The data collection is an important part of our design consulting for new builds as well as under-performing facility renovations. The dataset includes plant type(s) / count, building and site characteristics (floor area, climate), energy consuming systems (HVAC, electrical and plumbing), utility costs, occupancy profile (operational days and hours), and floor space usage.

Utilising our proprietary data in collaboration with key stakeholders (including owners, managers, design teams, and speciality consultants) provides for a comprehensive, actionable discussion around optimal facility design, equipment specification, and preliminary project costs.

Gain the benefits of cultivation space programming

The goal of cultivation space programming is to ensure every square foot of your facility is maximised in order to achieve a high performance indoor cannabis cultivation operation. By utilising thoughtful cultivation space programming techniques, you can design and construct a facility with competitive advantage both today and into the future.

For more information about how cultivation space planning can benefit your project, contact Lucas Targos at +1 970 596 2543 or email CSP@urban-gro.com.

Lucas Targos

urban-gro, Inc

+1 970 596 2543

CSP@urban-gro.com

www.urban-gro.com

This article will appear in the second issue of Medical Cannabis Network which is out in April. Click here to get your free subscription today.