Tristan Williams, Technical Director of Finsen Tech Group outlines key aspects to consider when purchasing UVC disinfectant products.

Tristan Williams, Technical Director of Finsen Tech Group, is a passionate advocate of the critical role that technology can play in reducing the risks of infection and the importance of self-regulation for emerging technologies.

Step into the UVC light (carefully)

Environmental disinfection has become the new battleground in the ongoing fight to reduce the risk of infection transmission. Evidence demonstrating the persistent contamination of environmental surfaces, despite traditional cleaning and disinfection methods, has led to a widespread acceptance that there is a demonstrative need for using supplementary disinfection technologies. Ultraviolet-C (UVC) disinfection is one type of non-touch technology proven to be a successful adjunct to manual cleaning in reducing environmental bioburden. The unprecedented COVID-19 pandemic, and the recognised efficacy of UVC against this virus, have greatly accelerated the growth of the UVC disinfection market. Unsurprisingly, this has resulted in a surge in ‘new’ UVC systems being offered for consumer purchase.

Power is everything with UVC

UVC is a disinfection technology that is entirely based on light (admittedly at a specific wavelength). As such, it is rightly and unavoidably governed by the laws of physics whereby just like a soundwave reducing in volume the greater the distance from the source, the same thing happens with UVC light.

There is a reduction in UVC intensity over distance, and therefore the more UVC power you have to begin with, the more effective the system will be over distance. For this reason, it is critical to know, understand and ask any potential UVC supplier that you are considering purchasing from the exact UVC output of their system expressed as UVC watts.

UVC is generated as a percentage of electrical input (i.e. it takes power to create), the amount of UVC light generated is critical for dose calculations.

Buyer’s tip

Many UVC suppliers will provide their electrical consumption in watts rather than the UVC output. Ask for clarification or the datasheet on the bulb/LED/emitter (a reputable OEM will have these on file) prior to purchase.

Log reduction (on what?)

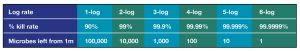

Log reduction is a mathematical term used to express the relative number of living microbes eliminated by a disinfectant and corresponds to inactivating 90% of a target microbe with the count being reduced by a factor of 10. The table below illustrates this:

A simple way to remember what it means is to simply ‘count the nines’ (i.e. 90% has one nine and is one log, 99% has two nines and is two log and so on).

However, it is critical to point out that different organisms require different amounts of UVC to be destroyed. So, when manufacturers make a claim of ‘kills 99.9999%’, the question to ask is ‘99.9999% of what exactly?’

If the manufacturer is testing on an organism that requires only a relatively low dose (COVID-19 for example), then their product will achieve a higher log reduction than if used with a harder to kill organism (e.g. MRSA).

Furthermore, if the claim is made without reference to an organism, then it is almost meaningless (see the following examples).

Buyer’s tips

Ask for details (the burden of proof lies with the manufacturer)

Ask for details of log reduction on which organism, (is it relevant to you?)

Ask for details of which material it was tested on (is it relevant to you?)

It is about time

UVC dosage is a relatively straightforward calculation, and it is entirely based upon duration, or more simply, time.

Whilst all manufacturers acknowledge that time is important as this affects availability of rooms and areas that you are seeking to disinfect with UVC, it is directly related to the power (amount of UVC) that the system can produce.

Faster is not necessarily better as to perform only a partial disinfection in order to reduce the cycle time, means only a certain number (or a certain type) of organism will be destroyed.

Questions to consider

- How accurate is the time calculation?

- What methodology do they use? Timer? Room scanning? Reflective dose? What are the tolerances for error (both machine and human)?

- When is the time calculated?

- At what point is the time calculated? Before the cycle? During the cycle?

- Why is their time calculation better than other systems?

- Where is the time calculated?

- Is the time calculated in the room? Outside the room? From a book/table or based on real time room data?

- What organism are they aiming to provide a terminal dose for? MRSA? C-Diff?

UVC safety

UVC is a low-risk light source, however, no personnel should be in the room at any point during the treatment (for room disinfection). As such, it is highly recommended to check that the system you are considering is safe to use. The system must have been exhaustively tested and rigorously designed to always ensure safety, and should feature the following active safety systems.

Emergency stop

There should be at least one easy to access emergency stop button mounted on the handle at waist height. These must have full authority over the entire system and if used will cause immediate shutdown, but also prevent further operation of any system.

Stable structure

The base should be supportive enough to ensure that there is no risk of toppling, and it should be able to traverse elevator thresholds and small cables easily. The castors should ideally feature both a directional and motion brake ensuring that your system stays where it needs to.

Motion detection

The most important feature that must be integrated is PIR (heat and motion) sensor. Ideally these should be built into the handle at waist height (to ensure clearance against beds and furniture), and these sensors must have full digital authority over the entire system in the event of an intrusion. Any movement when the system is operating will result in an instant shutdown (as well as the system not letting you begin a cycle if the room is not still for a set period).

Safety is paramount above all other requirements. Ask for details on active safety systems, how they work, response times, sensitivity, range, and effectiveness.

Adapt and evolve

This is one of the most straightforward but overlooked aspects of UVC disinfection systems but is critical if you are going to extract maximum value from your machine. It is important to consider not just where you are intending to use the system now, but where you feel needs may arise in the future.

Size

Simply, will it fit where you want to put it. Ensure that you ask for dimensions, weight etc, but the most overlooked criteria is height. Many systems are very tall, and this can cause difficulties using the system (door access, low ceilings etc), but also when transporting (fitting in a vehicle, pushing along a corridor – can you see over the top?) These are simple checks but can make an enormous difference. A useful yardstick is to check the size of the machine against the footprint of a wheelchair as that will allow you to take advantage of existing accessibility pathways.

Power

220v or 110v? Which do you need? Check that the system will function on the voltage that you need for your location. Due to the use of both voltages across the globe, some systems will automatically function on both. Please do ask though, the last thing that you need is to have a system arrive that you cannot physically use!

Make sure that your machine can adapt to your needs rather than you adapting to the machine’s needs. The more adaptable your system is, the more areas you will be able to disinfect.

Service and support

Service is everything. No matter whether your product is very expensive or very cheap, at some point, you will need to reach out for after-sales support and service. This could be in the form of training or technical support, or it could be in a fully-fledged breakdown scenario. Here are 16 key things you should look for in the after sales support of the product that you purchase:

- Functionality – does the product and the service support meet your needs?

- Price – is it priced fairly?

- Convenience – is it easy for you to use the service?

- Experience – are they experienced in their roles and with their product?

- Performance – will the contract be delivered with suitable SLA to guarantee performance?

- Efficiency – is the service/support delivered effectively and efficiently?

- Compatibility – is the service/support compatible with your needs and function?

- Empathy –does the service provider understand your needs/role/application?

- Fairness – is the pricing/terms of service/contract length fair?

- Transparency – are the service/support provider honest and transparent?

- Control – are you in control of the service/support?

- Options – is there freedom of choice? Tiered options?

- Information – will you receive full information on all contract reports/deliverables?

- Accessibility – is it easy to get hold of them? Are your requests being listened to?

Remember, when you are choosing a product, you are also partnering with their service provision for a long period. Making the right choice is key to a seamless integration of UVC disinfection into your workflow.

It is vital to consider the service aspect as much as the performance and cost of the system itself. Choosing the right partner for you will make an enormous difference in the long term.

Proof for your purchase

When you choose a UVC disinfection system, you are choosing it for a reason. You have a need to terminally disinfect an area or object. For that reason, it is fundamental to ensure that the products you are evaluating have product specific supporting data.

Why product specific? Well, that is simply down to the enormous number of variables in UVC disinfection systems that we have previously discussed. Reflector performance, type of tube, power, dosage calculation etc, all of these have a profound effect upon the actual effectiveness of the product to meet your needs and provide terminal disinfection.

The data should be:

- Product specific – not a generic referral to similar products data;

- Relevant – on a microorganism similar to one you need to eradicate, and the environment should be similar as well;

- Published – it should be published on a recognised site;

- Peer reviewed – reviewed by key opinion leaders within the industry;

- Concise and clear – the objectives should be outlined at the start and results clearly defined; and

- Use recognised methodology – using test protocols that are a standard industry practice.

This is the ultimate question: will it do what you want it to do, when you want it to do it? Ask for clarification, check for validation and do not be afraid to push for answers.

This article is from issue 19 of Health Europa Quarterly. Click here to get your free subscription today.