Pioneering cannabis and hemp processing company, PURE5, take us on an insightful journey through the fascinating process of cannabis production, elucidating how their industry-leading technology ensures the most optimal cannabis products.

Cannabis is one of the fastest-growing industries of the modern era, experiencing a rapid evolution over the last 10-15 years. There are two main trends in the cannabis industry: the supply chain approach – producing commodity cannabis products with a compliant label in volume, and producing state of the art boutique cannabis products. The techniques and equipment employed from the growing process to the end product are vital in ensuring the highest quality cannabis products, with good farming practices essential to conserving the original and best genetics. However, those who work in the sector need to navigate an array of challenges before they see their product on the market. How do you handle your growth, harvesting, pre-processing, processing, compliance with the THC regulations, and creating top-notch products while maintaining your process time to market and keeping costs low? Let’s take a journey through the entire process, learn how to be competitive, and anticipate what is coming ahead of the curve.

Growing Cannabis

Growing is the first step, and although cannabis may seem easy compared to other crops along the way, everyone soon finds out that is not the case. Selecting the right genetics, keeping compliance with the regulations, following the market demand, and offering the biomass in proper compliance are most often challenges. There are really two perspectives in the scope of the market demand: Grow for commodity and volume at a low price or grow high-quality boutique strains for medicinal use.

Growing for commodity means that you are producing only the major cannabinoids, which is your value to the end product. For example, growing for CBD isolate can happen from any strain without taking into account the minor cannabinoids. The market would pay only for the major cannabinoid content and will promote it in the cannabis products.

Growing medical cannabis requires the delivery of a complete profile of major and minor cannabinoids that are tailored toward specific medical conditions or experiences. There are over 100 cannabinoids now known to science and over 3000 terpenes, the combination and effects of which have been known for centuries and have been rediscovered recently by modern chemistry.

Choosing the correct market is the most important step to take before selecting the genotype variety and the proper strain to grow. Besides the medicinal values, there are plant physiological values that one needs to know, such as how much water, Sun, light exposure, temperature, vegetation days, and flowering and seeding days the strain requires.

PURE5 developed a new EU registered vertical growth genetics that is crossbred with US stable and flavourful hemp variety. The method can increase your flower production up to ten times compared to the North American way of growing large bushy plants with large spacing in between. The close vertical growth requires less water, almost no weed control, automated harvesting and, of course, good fibre to post-process.

PURE5 released its unique EU certified strain variety called PURE5 in 2 genomics – PURE 5.1 for straight oval plant and PURE 5.2 for bushy style plant. The variety is an enhanced cannabis terpene profile based on Chery Wine US strain. The result of this year’s hemp grow of the PURE5.1 variety is one-ton biomass from every 400m2. That converts to 2.5kg dry biomass from 1m2, which is five times more compared to the bushy style average of 0.5 kg/m2.

Harvesting the crops

Harvesting can bring a significant capital expense if not in sync with the genetics chosen. For many years, the EU recognised hemp varieties had been grown for fibre utilising large scale agricultural grow fields with fully automated harvesting. However, the US concept of medicine brought confusion into the well-established EU industrial hemp growing sector. Now, to grow medicinal crops, there are new regulations to be reviewed, further watering and planting practices to be deployed, new harvesting machines to be used, and all of that for the rush of better flowers.

We encourage the EU genetics to be adapted to the traditional EU grow for automated seeding, grow, and harvesting. PURE5 registered an improved EU variety for vertical growth and automated fibre production with ten times more oil and terpene production. Wet harvesting and then flower bucking are preferred as the most cost-effective ways to handle hemp before further post-processing. In large grows for commodity hemp, the drying is often done before the separation of flowers if the terpenes and minor cannabinoids are not a target.

PURE5 developed a simple harvesting unit that can be run by one person harvesting with adjustable height and collecting the flower and the fibre simultaneously. The harvester can harvest four to five acres an hour and is operated by a single operator.

Pre–processing cannabis products

The new medicinal oil genetics were not able to process the same way as the fibre genetics are processed. The flowers had to be either dry and bucked (separated) or wet bucked and dried. The conventional herb dryers were also not the most convenient since the fast dry damages the terpene profile and converts the cannabinoids. Further trimming and selecting the flower for smoking and extraction then sifting and separating the trim from the stick and seeds required specialised equipment as well.

In general, out of a one-acre crop of a good medicinal flower, a farmer can expect 1,000-3,000 lb of biomass where 30% will be good for pure smokable flower, 30-50% for extraction and the rest are sifted out as trash. For all of that, automated processing is required, or the competition will always be able to advance. Essential in pre-processing is drying at a low enough temperature to preserve the correct terpene profile while removing the moisture to less than 10%. There are freeze-drying and dry air-drying options.

The most cost-effective drying should not extend over 38°C for a one to two-hour process. The low temperature and short time do not allow the active cannabinoids to convert unless that is a requirement during drying. The flower is ventilated with dry air run by a terpene filter to condense the residual moisture.

PURE5 offers a complete pre-processing line, including flower wet bucking, drying and separating the flower for further biomass, seed, and fibre processing. Fibre separation and decortication for further industry utilisation.

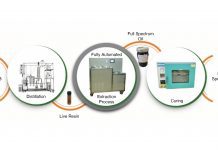

Processing cannabis products

Processing is directly correlated with the market demand and direction of cannabis products, commodities or medicinal. The commodity market looks for standardised raw materials used in volume goods production as distillate, isolate and full-spectrum oil. Besides, there are a number of exotic cannabis products such as wax, diamonds, shatter, live resin, etc. Of course, the full spectrum oil and all the exotics have to be remediated to compliant THC levels for their intended market. There is a rising demand for terpenes and live resin, which are the new market additions.

The most popular processing for commodity hemp is ethanol. The equipment is cheap, and it strips out almost all cannabinoids in a short time and delivers reasonable distillate and is a precursor for making isolates. The quality of the distillates made is not the highest but very price competitive. The CO2 extracts are trying to fill the void for higher quality and even deliver some limited terpene profiles at higher costs.

Extraction and separation of all main components of hemp allow the best product offering. Very often, that is done with multiple technologies to ensure product consistency. Producing high terpene live resin, isolated terpenes, full-spectrum, and broad-spectrum oils cover about the entire product range of materials used in producing vapes, eatables and cosmetics. That would be the smartest move to make and allow a wide range of customer experiences. The real question is can you do all of those with one machine, and how long the process would take.

PURE5 introduces a three in one process that can allow you to produce all six raw materials within a day. Considering the current industry practices, it takes weeks to get material ready to ship. However, the PURE5 solventless process and the combination with quick solventless remediation and low-temperature distillation can be accomplished within a day.

Compliance

Compliance is an important part of today’s hemp operation. It starts with the seed selection and ends up with the final product labelling on the shelf. The most important part of compliance is to always stay under the current state regulations. That in some cases is difficult considering the fact the aim toward good quality very often challenges compliance. There are three major issues one can bear: Is my flower under 0.2% THC? Is my extract under the 0.2% THC? and is my THC free product really non-detectable?

If the answer to those questions is no, then the situation must be resolved quickly. THC remediation of flowers and extracts is an easy process with the PURE5 machines. Remediation flowers without a colour change and leaving terpenes intact can be achieved with the 20L MAX R134a unit. The plant extract remediation is also easy with the 5L THCR solventless system that even a non-chemist can use. Then how do we answer the last question with on-site measurement capabilities?

Variety of products

The most popular cannabis products made from medicinal oil fall into three categories: cosmetics, supplements, and products for animals/pets. Those are fairly easy to make and can increase the margin of product sales up to five times. The key to the best-selling cannabis products besides the quality is the story. The consumer is looking for natural, organic, pure, and clean cannabis products to use.

PURE5 helps with the formulation and the correct preparation of the raw materials for the cannabis products. We offer a PBX Standard (Pure Botanical Extraction) programme that allows anyone to put a product on the shelf in the first week of building the lab.

Time to Market and cost

Time is money, and that is your time to market. Usually, the longer time you need to market is in direct proportion to the complication of your process, which can be more or less labour-intensive in your product cycle. Since no special post-processing is required with PURE5, the time to market can be as low as 24 hours.

The flower can be extracted wet or dry and sliced into two fractions – live resin and full spectrum concentrate. The first is utilised in smokable and pure oral oils (tinctures) and the second in eatables and cosmetic cannabis products. The gentle flower processing allows the flower to be reused after extraction for animal or pet food or further decomposed in organic fertiliser.

PURE5 understands the importance of ROI (return of investment) and proactively helps that process not to exceed four to six months. Below is a quick overview of the PURE5 technology economics while producing raw materials and end products in the cannabis field:

|

|

||||||||||||||||||||||||||||||||

|

|

Optimal cannabis products with PURE5TM

PURE5TM provides first-in-class technology for turnkey pre-processing, extraction and THC remediation with custom in-house manufacturing to evolve constantly and develop machinery for the hemp and cannabis markets’ needs. Its patent-pending technology is a hands-free, continuous-feed, closed-loop system with no winterisation necessary that increases productivity, yields and quality of each extraction at high capacity, industrial scale. In addition, to complete systems, PURE5TM offers an extraction system catalogue that includes high terpene extraction, pre and post-processing systems and supports system customers with services such as installation, site review, field verification, permitting, operation and more.