The STERISAFE PRO delivers safe, consistent, reliable whole-room disinfection.

Repeatability of results is one of the current challenges in disinfection, especially in healthcare facilities. While any new protocol or device is tested and validated prior to being accepted within an establishment, it is exceedingly challenging to guarantee consistent performance. The healthcare sector is currently under a tremendous amount of stress, with hospitals worldwide fighting to ensure that there is enough space and staff present to take care of patients. Current conditions are compelling already overworked staff to operate longer hours than usual; this can limit the efficiency of manual disinfection despite aiming for increased efficacy targets.

Automated room disinfection

Novel automated room disinfection (ARD) systems promise to alleviate these issues by delivering automated procedures which can be operated with minimal supervision – nevertheless, this is not always the case. To evaluate any technology’s efficacy and repeatability, it is necessary to consider the parameters on which that technology depends. For example, UV-based disinfection technology relies on the following:

- Light intensity

- Exposure time

- Distance between the light source and target

While the first two parameters can be easily measured and monitored throughout any UV-based disinfection cycle, the latter can prove challenging: room disposition, presence of furniture, and movement of the UV system may cause the distance to continually fluctuate. To ensure proper repeatability of the procedure, the UV system would have to be validated for every individual room, containing the same furniture placed in the same order.

For chemical-based foggers, the parameters of interest would be chemical concentration and exposure time. The former can sometimes be tricky to monitor because chemicals are usually ‘fogged’ into a room, meaning that their concentration would depend on droplet size, among other environmental factors. Typically, those droplets would be able to travel a distance inversely proportional to their size, which causes uneven distribution of the chemical inside the room to be treated. The smaller the droplet, usually the better the distribution, with vapourised chemicals typically performing the best in terms of equal distribution. In that sense, and in terms of repeatability of the procedure, foggers and vapourisers would depend on a reliable monitoring system and a sound technology that can guarantee equal distribution.

The STERISAFE PRO, which uses ozone-based technology to disinfect rooms and spaces, depends on three primary parameters:

- Ozone concentration

- Humidity

- Exposure time

With the appropriate sensors in place, these parameters can be easily monitored throughout any given cycle. Moreover, the use of gas as a disinfecting agent gives an advantage over chemical-based systems: as ozone obeys the physical laws which apply to gases, it will always diffuse from highly concentrated areas into lower ones, which means that up to a particular volume, an ozone monitor situated at a single point will be enough to monitor ozone concentration accurately within a whole enclosed space.

In terms of monitoring and repeatability, this gives gas-based technology a definite edge, with no significant variations in efficacy across all surfaces within a room (by comparison, UV-based technology is notorious for suffering from ‘shadow effects’, wherein it cannot disinfect what it cannot ‘see’).

Cloud-based platform

STRATOS is the STERISAFE cloud platform that allows users of the STERISAFE PRO to validate their disinfection process automatically. The full-depth disinfection cycle (FDDC) technology, which underpins the STERISAFE PRO, is the only technology within the ARD pantheon that allows users to validate their disinfection result based on hard data. There is no longer a need for a hygiene manager or member of cleaning staff to implement additional controls or fill out innumerable forms. This is possible because the platform can monitor all parameters in the room that are relevant for the disinfection success; and because our biocidal gas, the ozone, is able to reach every surface in a room equally.

Due to the development and integration of the STRATOS platform, clients are not only able to view the features mentioned above; they are also accorded access to all the data which is relevant to their individual disinfection process. STRATOS takes this data, stores it, and processes it to make it easy for users to see if a cycle was validated, which rooms have been disinfected and when. Furthermore, there are multiple features which enable clients to locate any STERISAFE PRO unit that is in use. Users will also be provided with a detailed disinfection cycle report, which includes additional information that can be relevant for the client. The report is available on the platform but can also be downloaded and sent to stakeholders during the disinfection process. The protocolisation and management of all disinfection processes will allow hygiene staff to monitor and document all disinfection processes centrally, even in larger groups where many sites are under the same administration. By tracking cycles and monitoring the data, the management team can take measures to prevent minor and major outbreaks.

STERISAFE PRO and COVID-19

Owing to the advantages it offers in terms of efficacy, repeatability and traceability, STERISAFE PRO is now used worldwide, especially in healthcare facilities. With the present pandemic continuing to cause issues across the world, novel technologies such as the STERISAFE PRO have found their usage extended to situations for which they were not necessarily initially developed. Due to the worldwide shortage of personal protective equipment (PPE) for healthcare workers, facilities have been investigating new ways to safely disinfect and reuse what was once considered single-use equipment, such as medical gowns, gloves, and masks. Following obligatory tests that would guarantee biocidal efficacy and equipment safety and integrity, STERISAFE PRO is now used in some facilities to allow the reuse of certain equipment.

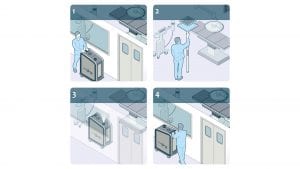

Placed in a dedicated room, the STERISAFE PRO operates as a stationary unit while the equipment which is to be disinfected is transported in and out of the room. On top of guaranteeing protection to healthcare workers, this operation can also be a significant cost saver for the operating establishment and an essential tool in the current times, which sees a high turnover of equipment.

While this specific usage of the STERISAFE PRO is the result of the unfortunate situation caused by the COVID-19 pandemic, the technology had previously been used in similar contexts: establishing a dedicated space for the use of the STERISAFE PRO to disinfect equipment means the user only needs to enact sealing protocols once. Because the advantage of using a gas that diffuses efficiently to all cracks and corners can rapidly become a liability in the case of inadequate sealing, the sealing procedure is paramount to any STERISAFE PRO operation. Therefore, a dedicated room allows the operator to guarantee the sealing integrity for all cycles and permits a higher turnover of cycles. For example, O’Flynn Medical (Cork, Ireland), routinely uses the STERISAFE PRO as part of its decontamination process within the facility to repeatedly disinfect rental products being supplied to hospitals, care homes and private homes across Ireland. In addition, O’Flynn combines its usage of the STERISAFE PRO with a mobile solution, by providing remote disinfection services using the STERISAFE PRO as well as providing the system for long term hire within Ireland.

STERISAFE has performed several efficacy tests by third party laboratories following the AFNOR NF T 72-281 protocol, which, up to October 2020, was the only testing standard developed for airborne room disinfection procedures. The STERISAFE PRO has demonstrated the efficacy of more than 99.99% removal for adenovirus, murine norovirus (MNV), Modified Vaccinia virus Ankara (MVA), and the SV40 polyomavirus. These are standard test viruses used to document efficacy, including for enveloped viruses such as coronaviruses. The NF T 72-281 standard was used as the principal model to write the most recent EN 27272 standard, which is now the only European-wide accepted standard.

These trying times have been a challenge in every way possible. However, they have also encouraged innovative solutions to be developed in the hope that they may contribute to the fight against COVID-19. The STERISAFE PRO was initially designed to prevent hospital-associated infections (HAIs) but has since proven its capabilities in several other sectors.

Currently, the STERISAFE PRO has demonstrated effectiveness in preventing further spread of COVID-19 by disinfecting indoor environments, as well as in-demand hospital equipment. Though the technology is a powerful tool, it is equally important that clients and operators of the STERISAFE PRO are informed and reassured about each disinfection cycle. The cloud-based platform STRATOS allows the collected data from the STERISAFE PRO to be stored and processed within a validation report that can be acceded by all necessary parties.

It is essential to be critical of the information stream, as insincere and/or ineffective solutions are currently roaming the internet. Even disinfection technology which claims to perform ARD has its limitations in real-world scenarios. To evaluate the viability of any technology, one should always consider the parameters by which it is evaluated – and either the NFT 72-281 for older results, or EN 17272 for any updated reports should be the only acceptable standard methodologies for ascertaining the efficacy of airborne disinfectant products.

Sorivan Chhem-Kieth

Product Manager – STERISAFE PRO

Amanda Munk Johnsen

Sales and Marketing Assistant

STERISAFE ApS

www.sterisafe.eu

This article is from issue 16 of Health Europa. Click here to get your free subscription today.