A new study has shown that nanofibre filters capture nearly 100% of coronavirus aerosols – a finding that could help mitigate airborne spread of COVID-19.

A team of researchers at UC Riverside and The George Washington University have compared the efficacy of surgical and cotton masks, neck gaiters, and electrospun nanofibre membranes at removing coronavirus aerosols for the air.

They found that the cotton mask and neck gaiter removed 45% to 73% of the aerosols, the surgical mask removed 98%, and the nanofibre filter removed almost all the coronavirus aerosols.

The findings have been published in the Environmental Science & Technology Letter.

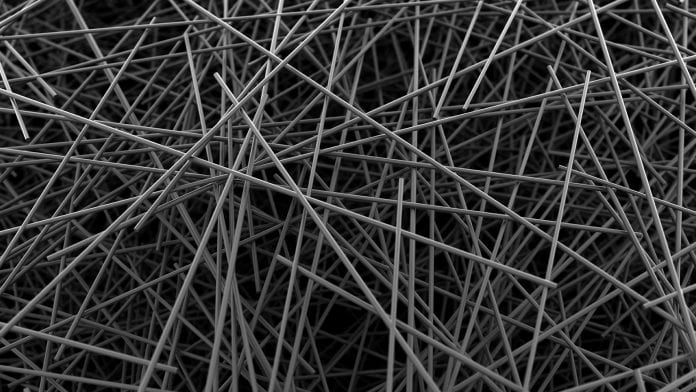

Nanofibre membranes

The filter, made from polymer nanothreads, blew three kinds of commercial masks out of the water by capturing 99.9% of coronavirus aerosols in an experiment. To date, all studies during the pandemic on mask or filter efficiency have used other materials thought to mimic the size and behaviour of coronavirus aerosols. The new study improved on this by testing both aerosolised saline solution and an aerosol that contained a coronavirus in the same family as the virus that causes COVID-19, but only infects mice.

Corresponding author Yun Shen, a UC Riverside assistant professor of chemical and environmental engineering, said: “Our work is the first study to use coronavirus aerosols for evaluating filtration efficiency of face masks and air filters. Previous studies have used surrogates of saline solution, polystyrene beads, and bacteriophages – a group of viruses that infect bacteria.”

The team produced the nanofibre filter by sending a high electrical voltage through a drop of liquid polyvinylidene fluoride to spin threads about 300 nanometres in diameter. The process created pores only a couple of micrometres in diameter on the nanofibre’s surfaces, which helped them capture 99.9% of coronavirus aerosols.

The production technique, known as electrospinning, is cost-effective and could be used to mass produce nanofibre filters for personal protective equipment and air filtration systems.

“Electrospinning can advance the design and fabrication of face masks and air filters,” said Shen. “Developing new masks and air filters by electrospinning is promising because of its high performance in filtration, economic feasibility, and scalability, and it can meet on-site needs of the masks and air filters.”