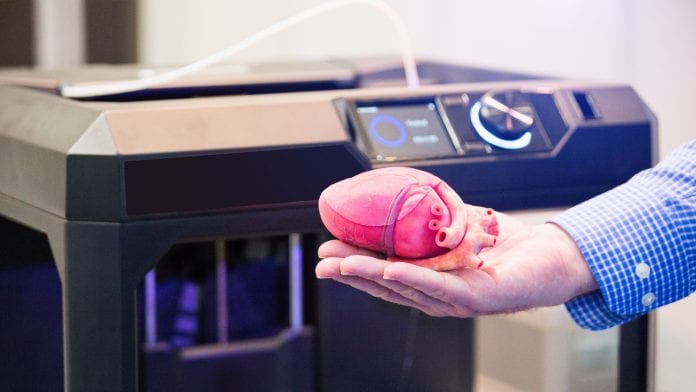

A new 3D-bioprinting method has tackled a common problem with the 3D-printing of organs which could help revolutionise organ transplantation.

Research into 3D bioprinting has grown rapidly in recent years as scientists seek to make complex biological systems from human tissues to entire organs, however, they have encountered issues with the distortion of biological materials or bioinks which build the 3D object being made layer-by-layer.

The research has been published in APL Bioengineering.

Tissue fabrication

When using biomaterials or bioinks to print 3D organs or body tissue, gravity can distort these soft and liquid materials. This common problem has presented a challenge to fabricating functional adult-sized tissues and organs, meaning most 3D-bioprinted tissue constructs to date have been relatively small when compared to the tissues or organs they are intended to replace. The problem is also a barrier to the long-term goal to supplement the limited donor supply for transplant.

The team of researchers from Carnegie Mellon University has developed the ‘Freefrom Reversible Embedding of Suspended Hydrogels’ (FRESH) 3D bioprinting approach, which solves the problem of bioink distortion by printing within a yield-stress support bath that holds the bioinks in place until they are cured, while still allowing for the movement of the extrusion needle.

The FRESH support bath also provides an environment during the printing process that maintains high cell viability, and uses a non-destructive print release by warming up the ink to 37°C to gently melt the support bath at body temperature.

Author Adam Feinberg, said: “Our goal is to be able to FRESH 3D-print complex 3D tissue and organ models out of a wide range of biocompatible hydrogel and cell-laden bioinks.”

The researchers have recently initiated several studies to FRESH 3D-print skeletal muscle, including controlling muscle architecture and regenerating muscle tissue after volumetric muscle loss.