UVC LEDs provide effective, efficient disinfection of air, water and the high-touch surfaces where they are most needed.

The COVID-19 crisis has highlighted the worldwide lack of readiness to manage pandemics and the associated need for consistent disinfection of the air, water and surfaces where pathogenic contamination occurs. As temporary quarantines around the world are slowly being lifted, there is an urgent need to implement safety measures to enable closer physical proximity between individuals, particularly in indoor or shared environments such as offices, hospitals, schools, restaurants, and transportation. Simple measures such as wearing masks, washing hands, and wiping surfaces with chemicals are either ineffective against certain microorganisms, time-consuming, or lack verifiable standards for compliance. Fortunately, UVC LED disinfection technology is enabling innovative solutions that can help create safer environments.

The need for safer water, air and surfaces inside buildings

Recently, we have seen a global trend towards ‘healthy buildings’, where buildings themselves promote wellbeing and social health, driven by the newfound demand for automated, documented, reliable disinfection of air, surfaces and water in shared spaces. For example, facility managers have started implementing steps to ensure dispensed water is free of harmful pathogens or biofilms which may grow in deteriorating infrastructure and residual water left untouched for prolonged periods of time, such as during the lockdowns which took place earlier this year. A targeted approach to define which waterborne pathogens were likely to be present and how they were to be removed has pushed water cooler manufacturers and service providers to integrate UVC LED solutions, which can efficiently tackle the problem at the point of dispense. For example, a Klaran WR, powered by two Klaran UVC LEDs, provides more than 99.99% disinfection of pseudomonas at two litres per minute for up to seven years without maintenance; and allows for self-cleaning functions to prevent biofilm formation in residual water.

The current pandemic has shifted the focus towards reducing the risk of transmission of pathogens in air and surfaces in offices, schools, hospitals, restaurants and other shared spaces. Recently, the emergence of innovative products such Big Ass Fans’ Clean Air System Haiku with UVC, which uses Klaran UVC LEDs produced by Crystal IS, has demonstrated the efficacy of UVC LED solutions in treating airborne pathogens while being economically viable.

The risk of pathogen transmission increases dramatically in shared spaces with frequency of usage, ventilation, and ability to maintain recommended social distances. Elevators are of particular interest due to the confined spaces which do not allow for proper social distancing, poor ventilation and the necessity for elevator users to make contact with high-touch surfaces. With over six million installed elevators in Europe and approximately 150,000 new installs every year, the opportunity to make a positive impact is tremendous. Not surprisingly, manufacturers and servicing companies are seeing a strong demand to integrate these solutions. When elevators undergo regular maintenance or upgrades, they are placed out of order and people are redirected to a fewer number of operational elevators. This increases the number of button presses and people breathing the same air in a smaller number of elevators. The inconvenience to the end user as a result of elevator downtime can last for several days. This situation has exerted considerable pressure on facility managers and service contractors to reduce the number of visits and avoid removing elevators from the network for maintenance. This is a unique opportunity to re-engineer the cabin interior of elevators to self-clean.

Imagine a small device, no bigger than a smartphone, which can be positioned above the elevator keypad to disinfect the buttons after every touch, connected to a proximity sensor in order to ensure safety and compliance. Imagine the luminaire in the ceiling of the elevator recirculating the air and disinfecting it at every pass, reducing the transmittivity of pathogens such as H1N1 or COVID-19 over time. Now imagine a technology that has no hazardous material and can predictably operate over several years without the need for replacement, upgrade or maintenance. This is the opportunity UVC LEDs provide for designing innovative disinfection solutions.

Benefits of UVC LED disinfection technology

UVC disinfection is a physical process that disrupts the DNA/RNA of microorganisms so that they can no longer reproduce and thus cannot spread. UVC light is proven to effectively inactivate drug-resistant bacteria and differing strains of viruses.

While conventional mercury lamps have long been used as a UVC light source for disinfection applications, safety and reliability concerns, cost of ownership and regulations around the ban of mercury devices have driven the development of alternative UVC sources for disinfection. UVC LEDs are mercury-free devices that offer instantaneous on/off operation, ability to cycle without impacting lifetime, extraction of heat in the opposite direction of UVC light, and low costs of maintenance – each of which is a drawback of mercury lamps.

UVC LEDs have been under development for over two decades; and the first commercially available device was released six years ago by Crystal IS. Since then, the technology has seen substantial growth in terms of power, production capability, and ability to generate output at the most efficient germicidal wavelength (260nm to 270nm). These characteristics have enabled the integration of UVC LEDs into a variety of disinfection applications in water, high-touch surfaces, and most recently air disinfection, increasing the quality of products and features available to the end user, differentiation to original equipment manufacturers, and cost savings to operators and managers. They also allow for UVC LEDs to be fully integrated to the wider facilities and services, for example through connection to proximity sensors.

Other technologies have surfaced as well: excimer lamps offer a promising perspective but lack the robust and prolonged biological studies and certification required for the direct use on humans (learn more about the differences between germicidal UVC and ‘far UV’ by visiting the Klaran Knowledge Base), and the use of ‘antiviral’ coatings to inactivate viruses, which require regular disruption and external workers to apply the coating. UVC LEDs are widely seen as the most promising technology for applications such as self-cleaning elevators and for healthy buildings in general.

Research showing the effectiveness of UVC LEDs for disinfection

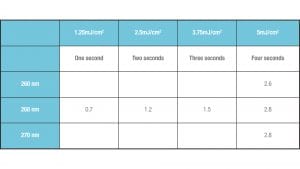

Studies have shown that UVC LEDs work effectively on pathogens such as SARS-CoV-2, the virus that causes COVID-19. For example, Crystal IS initiated research with Boston University’s National Emerging Infectious Diseases Laboratories (NEIDL) to assess how SARS-CoV-2 responds to varying doses of UVC light emitted by Klaran UVC LEDs across the 260nm to 270nm wavelength range. Based on the results, shown in the table below, a dose of 5mJ/cm2 at 268 nm inactivated 99.8% of the virus; additionally, a UVC dose of 6.25 mJ/cm2 resulted in a 99.9% reduction of the virus.

Log reduction as a function of dose and LED peak wavelength

The SARS-CoV-2 virus is very sensitive to UVC light and requires low doses of UVC at 265nm to be inactivated (SARS-COVID type viruses are extremely sensitive to wavelength, therefore a higher dose is required at longer wavelengths to achieve the same disinfection level, a behaviour demonstrated by most pathogens). However, when comparing the results of this study to the results published by the University of Miyazaki (which used UVC LEDs that emit at 280nm), there appears to be a drop in efficacy beyond the 270nm wavelength. This type of information highlights the importance of UVC LED wavelength when it comes to germicidal efficacy.

While the COVID-19 pandemic persists, other pathogens such as common flu present a continued threat to our health and safety. Much like SARS-CoV-2, the spread of Influenza A could be reduced by implementing disinfection solutions that are built with UVC LEDs. Microbial studies have shown that a device with Klaran UVC LEDs can disinfect Influenza A (H1N1) virus on a surface by a reduction of more than 99.998%.

Additionally, previous work has demonstrated the efficacy of air disinfection systems with relatively low power requirements on increasing the renewed/fresh air injection capability of ventilation by a factor of three. The air circulation speed, which was originally thought to be too high for UVC LED technology, can be balanced with smart design – particularly around internal reflectivity to UVC of channels where power requirements can be decreased by up to two orders of magnitude through the use of highly reflective materials. This reflects the learnings from point-of-use water disinfection, where UVC LED water reactors (such as Klaran WR) have replaced mercury lamp chambers 100 times more powerful to produce the same disinfection result, while increasing longevity and reliability.

Recently, Lai et al from the Chinese University of Hong Kong (DOI: 10.1111/ina.12619) showed similar disinfection performances in an upper-room UVGI system using UVC LEDs against a UVGI system using a mercury lamp. The UVC LED solution, using Klaran UVC LEDs, had 200mW output at 265nm, whereas the mercury lamp system used a 21W (in other words, over 100 times the optical power of the LED system). It is therefore clear that disinfection can be dramatically optimised through the use of UVC LED technology; and mindsets must be changed to rethink solution design in order to best fit user requirements.

Finally, the level of disinfection needs to be revisited from previous static definitions used in single pass applications such as surfaces or water, where exposure time was the limiting factor. Instead, air disinfection in practical terms aims to minimise over time the risk of pathogen transmission and should adapt to the reality of dynamic end-user flow air recirculation. We are already seeing this change occur and systems being rated as a function of number of people in a room (DOI: dx.doi.org/10.1021/acsnano.0c04596) or the volume of the space (DOI: 10.1164/rccm.201501-0060OC).

Looking ahead

While UVC LED technology is already commercially and technically viable, the quality of the products reaching the market differs dramatically, as no certification, standards, test protocol or minimum target requirements are in place. The industry will eventually converge towards such standards, as it already has in water disinfection. In the meantime, it is essential that such products be developed according to the initial guidelines provided by industry leaders such as Crystal IS and validate any products with microbiological tests to qualify the efficacy. Crystal IS is a current leader in standards development in a range of verticals, using a pathogen-first approach through its microbial lab facilities in New York.

It is time for bold moves: disruptive technologies are seeing faster adoption than usual.

The urgency to bring solutions to market is heavily driven by the growing threat of new and existing viruses, bacteria and other pathogens in our environment. When it comes to healthy buildings, self-cleaning elevators may be one of the most critical places where disinfection solutions are needed, since it is the space where pathogen transmission is very high. Of course, there are numerous opportunities to add UVC LEDs to create safer environments. Solutions exist and need to be introduced to market.

About the author

Dr Kevin Kahn is responsible for market development in EMEA at Crystal IS, specialising in UVC LED solutions for infection prevention and water quality management. He holds a BSc in electrical engineering from EPFL, an MRes and a PhD in applied physics from Imperial College London; and was a research fellow at the National University of Singapore. For his contributions to UVC LED technology, he has been awarded the 2018-2019 IUVA best paper award, elected to the standard committee of Watercoolers Europe in 2019, and vice-chairs an IEEE-IAS working group on air disinfection.

Dr Kevin Kahn

Market Development Manager

EMEA

Crystal IS

+1 (518) 271 7375

Kahn@cisuvc.com

Klaran.com

This article is from issue 15 of Health Europa. Click here to get your free subscription today.