New research illuminates the necessity of extending the shelf life of vaccines and finds a new approach to mitigate common vaccine problems.

It is reported that almost half of all vaccines go to waste. This is mainly due to logistic obstacles in transporting vaccines to diverse regions of the world. Additionally, the temperature of vaccines must be regulated throughout the process of manufacturing and delivering the vaccine. Maintaining a constant temperature is also important to sustain the shelf life of vaccines, but this can be challenging in Sub-Saharan Africa and other developing regions.

To improve the shelf life of vaccines, scientists from ETH Zurich’s Macromolecular Engineering and Organic Chemistry Labs and entrepreneurs from Colorado-based Nanoly Bioscience worked together to develop a safe, versatile platform to increase the thermal stability of vaccines.

The scientists published the findings in Science Advances.

Improving the shelf life of vaccines

“Think of it like an egg,” explained Bruno Marco-Dufort, a Doctoral Researcher in Professor Mark Tibbitt’s Macromolecular Engineering lab. “At room temperature or in the refrigerator, the egg maintains its viscous-like protein structure, but once it hits boiling water or the frying pan, its structure changes permanently.” It is similar to the proteins in a vaccine – once exposed to certain temperatures – they clump together. Cooling them down again will not reverse their denaturation – you cannot ‘un-cook’ the egg.

Marco-Dufort and his researchers developed a new type of hydrogel. The gel is a biocompatible, synthetic polymer known as “PEG”; it protects complex molecules such as the proteins found in vaccines, antibodies, or gene therapies. The researchers described this technology as “molecular Tupperware”, it encapsulates the proteins and keeps them separated, elongating the shelf life of vaccines. Furthermore, the technology enables the proteins to survive a high range of temperature fluctuations. Instead of the traditional +2 to +8 °C (35 to 45 °F) range for the cold chain, encapsulation allows for a range of 25 to 65 °C (75 to 150 °F). Most importantly, the encapsulated cargo is released by adding a sugar solution, enabling easy on-demand recovery of the vaccines at their point of use.

Reducing health risks associated with cold chain storage

Alongside improving the shelf life of vaccines, hydrogel technology could potentially reduce costs and health risks associated with cold chain storage. “In 2020, the overall market for cold chain services (from manufacturing to distribution) was $17.2bn and forecasted to rise,” the researchers reported. Rising costs pose detrimental consequences for public health and public trust if vaccines arrive via a compromised cold chain.

“Most vaccines are sensitive to hot and cold. This creates a large barrier for global immunisation campaigns because vaccine distribution and administrative costs often exceed the costs of production,” explained Marco-Dufort.

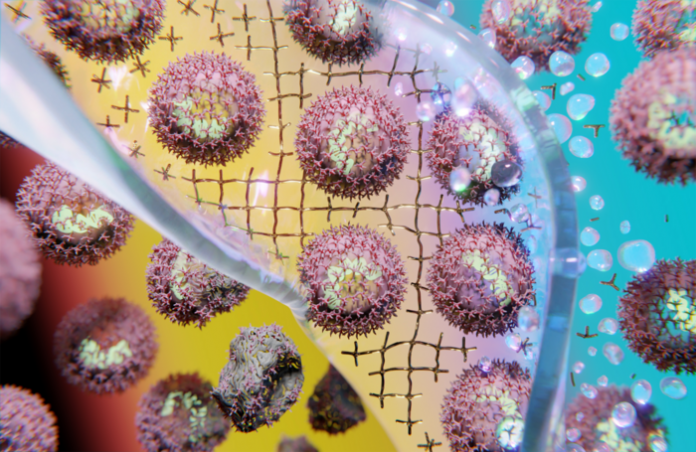

The researchers noted that more research, safety studies, and clinical trials are required before hydrogels can be implemented for vaccine distribution. The more immediate use of this technology can be applied when transporting heat-sensitive enzymes used in cancer research or protein molecules for research in lab settings.