Tedlar’s pioneering PVF film technology is creating a safer and more sustainable environment for industries including transportation, electronics and healthcare.

DuPont™ Tedlar® is a versatile polyvinyl fluoride (PVF) film. For more than 60 years, Tedlar PVF films have provided durable, long-lasting protection and timeless aesthetics to many types of surfaces that are subjected to harsh environments. Available as transparent film or in a variety of colours and gloss levels, it is typically applied to the surface of other materials to provide added durability, cleanability and chemical resistance. Its applications span a range of industries, including transportation, aerospace, building and construction, graphics and signage, electronics, and photovoltaics.

Polyvinyl fluoride is naturally transparent and flexible, enabling its use without addition of any co-resins or plasticisers which can be susceptible to UV degradation, chemical attack, or provide nutrients to microbes. Most Tedlar films can be stretched in any dimension to more than twice their original length without breaking, giving them superior formability, durability, and resistance to impact damage.

Chemical resistance and compatibility of Tedlar

Chemical resistance refers to the ability of a material to maintain its colour, gloss, dimensions and mechanical properties during and after contact with chemicals. Chemical compatibility further details the lack of chemical reaction between a material and a chemical under consideration.

The strong chemical resistance of Tedlar originates from its highly inert chemistry. The incorporation of fluorine into the monomer unit draws electron density away from the linear carbon backbone, effectively creating stronger bonds throughout the entire polymer chain. As a result, the PVF resin does not dissolve in any known solvent at room temperature, does not absorb water, and is inert to attack by strong acids and alkalis, providing the highest level of resistance to chemicals, pollutants, corrosive agents, cleaners and disinfectants. The chemical resistance also prevents the ingress of staining agents and enables the removal of stains or graffiti from the surface without ghosting, using a wide range of cleaners and solvents.

Tedlar PVF films have extremely high chemical resistance and compatibility with acids, bases, oxidisers, a variety of solvents including polar, non-polar, aromatic, aliphatic, hydrocarbon and chlorinated solvents, and other harsh chemicals. Even under extreme conditions with high concentrations, extended exposure times, and high temperatures, the Tedlar film retains all or most of its original properties and appearance. In fact, there are no known solvents for Tedlar films at temperatures below 149°C.

In addition to their chemical resistance and compatibility, Tedlar films are impermeable to greases and oils. This makes them easy to clean as many common staining agents will remain on the surface of the film, from which they can be easily removed by cleaning, restoring the original surface aesthetic completely with no shadowing or ghosting.

Hydrolysis resistance of Tedlar

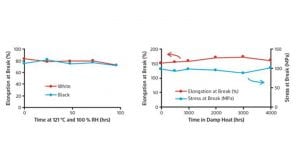

Tedlar PVF films do not readily absorb water and are highly resistant to degradation by hydrolysis. Even under an extremely harsh Highly Accelerated Stress Test (HAST) at 121°C and 100% relative humidity, the films have no change in mechanical properties and no visible colour change after 100 hours. In a longer-term damp heat ageing test at 85°C and 100% relative humidity, the films exhibit similar mechanical and colour stability even after 4000 hours of exposure. Typical hydrolysis resistance results are shown in Fig. 2.

The importance of proper protective overlay film selection

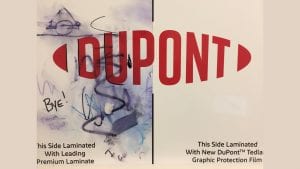

Fig. 3 shows a photo from a test in which permanent marker was applied to a sign whose right side is laminated with Tedlar PVF film and left side is a premium cast PVC vinyl. A 100% acetone nail polish remover was used to attempt to clean off the permanent marker. The side with Tedlar PVF film was successfully cleaned with the acetone, while the ink penetrated the vinyl laminate leaving permanent stains. When cleaning, the stains were smeared over the surface and the vinyl eventually was irreversibly damaged.

Resistance to disinfecting solutions

While cleaning agents can easily restore the original surface aesthetic of Tedlar films, most cleaners do not destroy viruses, bacteria and fungal pathogens. For this, disinfecting solutions are often required. While these solutions can be highly detrimental to many materials after repeated application, causing discolouration or permanent structural damage, Tedlar PVF films have outstanding resistance to the whole range of commonly used disinfectants.

Table 1 shows the resistance of a PVC substrate protected with Tedlar PVF film. The disinfectants used represent the classes of disinfectant solutions that are most commonly used in hospital environments. A 2.5ml solution was deposited and left on the surface each day for five days. At the end of the five-day test, the surface was cleaned to remove any residues and assess the impact on the surface. A rating of ‘E’ denotes that there was no perceptible change of either appearance or mechanical properties after the exposure.

Tedlar PVF film has unique properties that make it an ideal surface protection material. No other surface protective film can offer the level of chemical resistance and compatibility that Tedlar PVF films can offer. The durability of the films will ensure that the underlying materials look good and function well for decades even in the harshest chemical environments.

For more information on Tedlar PVF films, please visit tedlar.com.

DuPont™, the DuPont Oval Logo and all products, unless otherwise noted, denoted with ™, ℠ or ® are trademarks, service marks or registered trademarks of affiliates of DuPont de Nemours, Inc.

This article is from issue 17 of Health Europa. Click here to get your free subscription today.